As the world seeks greener, more sustainable construction methods, hempcrete has emerged as an innovative and eco-friendly alternative to traditional building materials. But what exactly is hempcrete, and why is it gaining so much attention in the green building community? This blog explores the science behind hempcrete, its production, applications, and the numerous environmental and practical benefits it offers.

Whether you’re a builder, architect, or eco-conscious homeowner, understanding hempcrete could change the way you think about construction.

What Is Hempcrete?

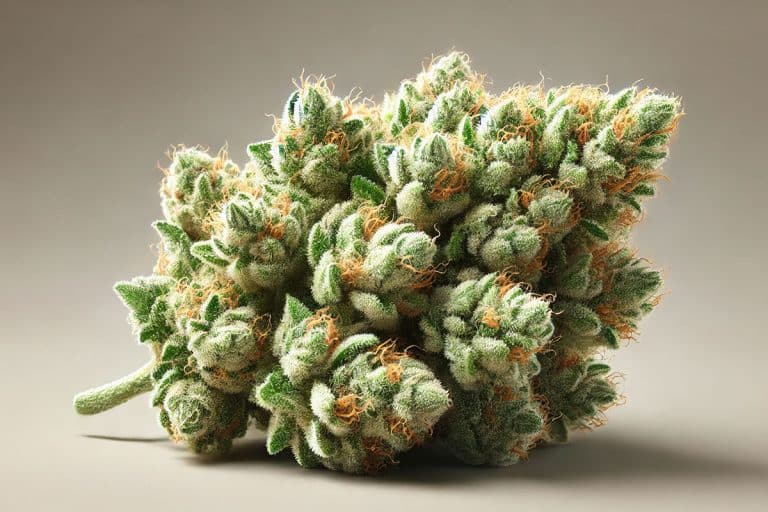

It is a bio-composite material made by mixing the woody core (hurds) of the hemp plant with a lime-based binder and water. The result is a lightweight, breathable, insulating material that can be molded into blocks, panels, or sprayed onto structures.

Unlike traditional concrete, hempcrete does not contain cement or large amounts of sand and gravel. Instead, it relies on natural materials, making it far more sustainable.

How Is Hempcrete Made?

The key ingredients of hempcrete are:

- Hemp Hurds: The woody inner core of the hemp stalk. These fibers are lightweight and porous.

- Lime Binder: Usually hydrated lime or natural hydraulic lime, which reacts chemically to bind the hemp hurds together and harden over time.

- Water: Used to activate the lime and mix the ingredients into a workable slurry.

These components are combined in specific ratios and then formed into blocks or sprayed onto a framework. Over weeks, the lime cures and carbonates, hardening into a solid but breathable material.

Hempcrete vs. Traditional Concrete

Unlike concrete, which is heavy, dense, and energy-intensive to produce, hempcrete offers several distinct advantages:

- Lightweight: Hempcrete is much lighter than concrete, reducing transportation costs and making it easier to handle on-site.

- Breathability: Hempcrete allows moisture to evaporate naturally, reducing mold and dampness issues.

- Carbon Negative: Hempcrete absorbs more CO2 during the hemp growing phase and lime curing than is emitted during production, making it carbon-negative.

- Non-Structural: Hempcrete is not load-bearing but serves as excellent insulation and wall infill.

Key Benefits

1. Environmental Sustainability

- Carbon Sequestration: Hemp plants absorb CO2 as they grow. When combined with lime curing, hempcrete locks away more carbon than is released, contributing to reduced greenhouse gas levels.

- Renewable Resource: Hemp grows quickly (in about 3-4 months) and requires fewer pesticides and fertilizers compared to conventional crops.

- Low Energy Manufacturing: Producing hempcrete consumes far less energy than Portland cement concrete, reducing environmental impact.

2. Excellent Insulation

Hempcrete has impressive thermal insulation properties. It keeps buildings warm in winter and cool in summer by regulating temperature effectively. This insulation reduces energy consumption and lowers heating and cooling costs.

3. Breathability and Moisture Regulation

Hempcrete’s porous structure allows walls to “breathe,” preventing moisture buildup, condensation, and mold growth. This makes it ideal for healthier indoor air quality and durable buildings.

4. Fire Resistance

Thanks to its lime content, hempcrete is naturally fire-resistant. It doesn’t burn easily and can provide valuable extra time during a fire emergency.

5. Durability and Pest Resistance

Hempcrete is resistant to pests such as termites, which often damage wooden structures. Additionally, it does not rot or decay, contributing to longer-lasting buildings.

6. Acoustic Insulation

Due to its density and texture, hempcrete provides excellent soundproofing, making it ideal for urban settings or noisy environments.

7. Non-Toxic and Hypoallergenic

Hempcrete contains no harmful chemicals or VOCs, ensuring a safe and healthy environment for occupants, including those with allergies or respiratory issues.

Applications of Hempcrete

It can be used in a variety of building applications:

- Wall Insulation: Often used as infill around timber frames, providing insulation and thermal mass.

- Exterior and Interior Plasters: Can be sprayed or troweled on walls to create breathable, insulating surfaces.

- Renovation: Ideal for retrofitting older buildings, improving insulation without heavy construction.

- Soundproofing Panels: Used in walls and floors for noise reduction.

Challenges and Considerations

While it offers many benefits, there are some limitations:

- Not Load-Bearing: Hempcrete cannot support structural loads, so it must be used with a frame (usually timber or steel).

- Curing Time: Hempcrete takes weeks to fully cure, which may extend construction timelines.

- Availability: Hempcrete materials and experienced contractors may be limited depending on region.

Why Hempcrete Is the Future of Green Building

With increasing global focus on sustainability and reducing carbon footprints, hempcrete represents a revolutionary building material that combines environmental benefits with practical performance. Its use in eco-friendly homes, commercial buildings, and public infrastructure continues to grow, helping reduce construction’s environmental impact.

Where to Learn More or Purchase Hempcrete Materials

If you’re interested in exploring hempcrete for your next project, seek suppliers who specialize in sustainable building materials. Many companies now offer hempcrete mixes, panels, and construction support.

Conclusion: Embracing Hempcrete for a Sustainable Tomorrow

It is transforming the construction industry with its unique combination of sustainability, performance, and health benefits. As a carbon-negative, insulating, and breathable material, it offers an eco-friendly alternative that doesn’t compromise on quality or durability.

Whether you’re a builder, architect, or homeowner passionate about green building, hempcrete is worth considering for your next project. Its benefits align perfectly with the urgent need to reduce emissions and create healthier living environments.